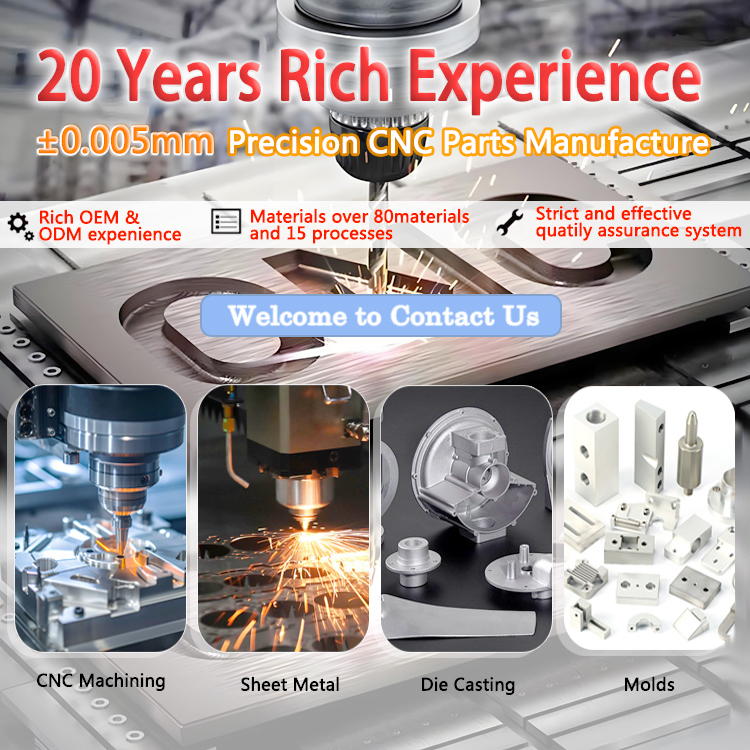

Custom Shaped CNC Machined Parts with 100% Inspection and Surface Roughness Min Ra 0.1~3.2 Precision Mechanical Parts

-

강조하다

100% Inspection CNC Machined Parts

,100% Guaranteed Precision Mechanical Parts

,Surface Roughness Min Ra 0.1~3.2 CNC Turning Milling Parts

-

재료 기능알루미늄, 황동, 청동, 구리, 경화 금속, 귀금속, 스테인리스 스틸, 강철 합금

-

표면 처리샌드 블라스팅, 양극화, 분말 코팅

-

그리기 형식dxf / dwg / step / igs / pdf

-

용인± 0.001 ~ ± 0.01mm

-

표면 거칠기Min RA 0.1 ~ 3.2

-

마이크로 가공마이크로 가공

-

CNC 가공CNC 가공

-

가공 유형부착, 굴착, 에칭/화학 가공, 레이저 가공, 밀링, 급속 프로토타입 제작, 턴링, 와이어 EDM

-

배달 시간3-30 일

-

물리적 표면 처리샌드 블라스팅, 와이어 드로잉, 샷 블라스팅, 연마, 롤링, 브러싱, 스프레이, 페인팅, 파우더 스프레이, 실크 스크린 인쇄, 패드 인쇄, 물 전달 인쇄, 전기 영동

-

화학 표면 처리푸르스름한 검은 색, 인산염, 산세, 전기 도금, TD 처리, QPQ 처리, 기화, 질화, 화학적 산화, 패시베이션

-

전기 화학 표면 처리양극 산화, 단단한 양극 산화, 전해 연마, 전기 도금

-

현대 표면 처리화학 기상 증착 (CVD), 물리 증기 증착 (PVD), 이온 이식, 이온 도금, 레이저 표면 처리

-

품질 관리임계 크기 위의 100% 검사

-

샘플 리드 타임1-2 주

-

원래 장소광동, 중국

-

브랜드 이름yuanwenyu

-

모델 번호OEM99, OEM

-

문서

-

최소 주문 수량1

Custom Shaped CNC Machined Parts with 100% Inspection and Surface Roughness Min Ra 0.1~3.2 Precision Mechanical Parts

Custom Shaped Hardware Accessories CNC Lathe Precision Mechanical Parts Processing

Product Description

| Service | CNC Turning/CNC Milling/Laser Cutting/Bending/Spinning/WireCutting/Stamping/Electric Discharge Machining(EDM)/Injection Molding |

|---|---|

| Available Materials | Aluminum, stainless steel, copper, iron, plastic, titanium alloy etc. |

| Size or shape | According to customer drawings or requests |

| Drawing Accepted | PDF, DWG, IGS, STP, XT, DXF, Pro/E, STL, STEP |

| Surface treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Tolerance | ±0.001~±0.01mm |

| Surface Roughness | Min Ra 0.1~3.2 |

| Delivery Time | 3-30 days after order with prepayment based on products structure and quantity |

SURFACE TREATMENT

| Physical surface treatment | sandblasting, wire drawing, shot blasting, polishing, rolling, brushing, spraying, painting, powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc. |

|---|---|

| Chemical surface treatment | bluish blackening, phosphating, pickling, electroless plating, TD treatment, QPQ treatment, carburizing, nitriding, chemical oxidation, passivation, etc. |

| Electrochemical surface treatment | anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc. |

| Modern surface treatment | chemical vapor deposition (CVD), physical vapor deposition (PVD), ion implantation, ion plating, laser surface treatment, etc. |

Quality Inspection

CUSTOMER REVIEWS

FAQ

Q1: Are you a manufacturer or a trading company?

A1: We are a 1500-square-meter factory located in Huizhou, China.

Q2: Can I get a quote without drawings?

A2: Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

Q3: Will my drawings be divulged if you benefit?

A3: No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

Q4: Can you provide samples before mass production?

A4: Sure, sample fee is needed, will be returned when mass production if possible.

Q5: How about the lead time?

A5: Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q6: How do you control the quality?

- Material inspection--Check the material surface and roughly dimension.

- Production inspection--Each production section will check the key dimensions and appearance. Before surface treatment, do a good job of product packaging to avoid bumps and injuries. And check visual inspection

- Sampling inspection--Check the quality before sending to the warehouse.

- Pre-shipment inspection--100% inspected by QC assistants before shipment.

Q7: What will you do if we receive poor quality parts?

A7: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.