Custom Precision CNC Turning Service with Laser Engraving and 100% Inspection Guaranteed for Stainless Steel and Aluminum Parts

-

강조하다

100% Inspection CNC Turning Service

,100% Guaranteed CNC Machining Service

,Laser Engraving Precision CNC Parts

-

재료 기능알루미늄, 황동, 청동, 구리, 경화 금속, 귀금속, 스테인리스 스틸, 강철 합금

-

표면 처리샌드 블라스팅, 양극화, 분말 코팅

-

그리기 형식dxf / dwg / step / igs / pdf

-

마이크로 가공예

-

CNC 가공예

-

기계가공 타입부착, 굴착, 에칭/화학 가공, 레이저 가공, 밀링, 급속 프로토타입 제작, 턴링, 와이어 EDM

-

스테인레스강 그레이드SS201, SS301, SS303, SS304, SS316, SS416

-

알루미늄 등급AL6061, AL6063, AL6082, AL7075, AL5052, A380

-

황동 등급HPB63, HPB62, HPB61, HPB59, H59, H68, H80, H90

-

구리 등급C11000, C12000, C36000

-

강철 등급온화한 강철, 탄소강, 4140, 4340, Q235, Q345B, 20#, 45#

-

플라스틱 유형ABS, PC, PE, POM, NYLON, PP, PEEK

-

CNC 기계25 세트 CNC 가공 센터, 12 세트 CNC 회전 및 밀링 컴파운드 가공 센터, 20 세트 CNC 선반

-

3D 프린팅 장비10 세트

-

품질 관리임계 크기 위의 100% 검사

-

원래 장소광동, 중국

-

브랜드 이름yuanwenyu

-

모델 번호YWY450, OEM

-

문서

-

최소 주문 수량50

Custom Precision CNC Turning Service with Laser Engraving and 100% Inspection Guaranteed for Stainless Steel and Aluminum Parts

Advanced Custom Precision CNC Turning & Laser Engraving Services

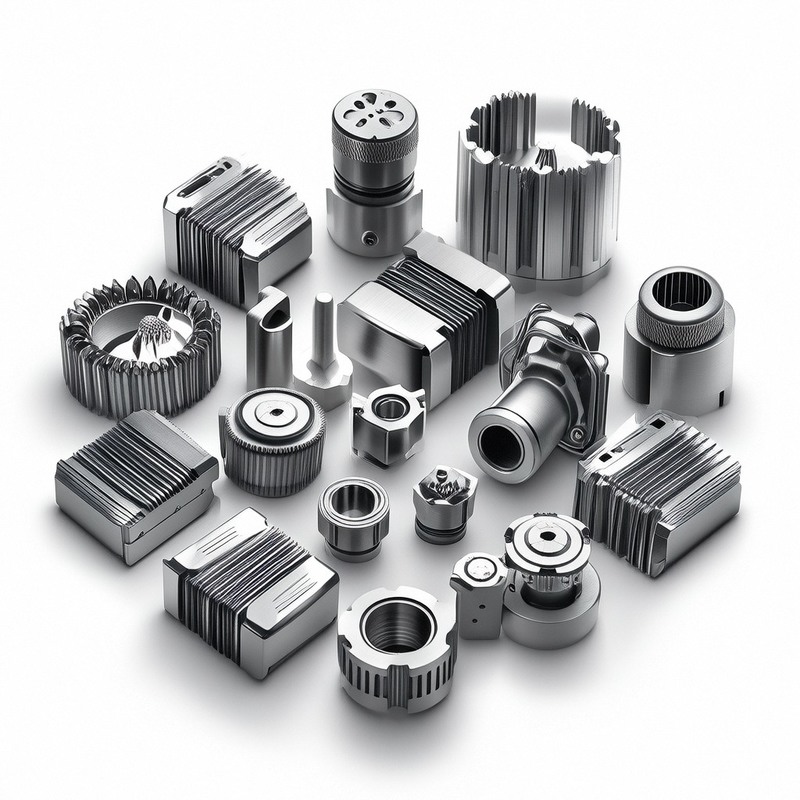

The products shown here demonstrate our manufacturing capabilities. We specialize in custom CNC machining for stainless steel, aluminum, and other metal parts with precision laser engraving services.

Small orders welcome - No minimum quantity requirements

Our in-house capabilities include: CNC Milling, Turning, Lathe, Wire Cutting, EDM, and laser marking for custom logos/designs.

CNC Machining Services

Our precision CNC hardware serves aerospace, automotive, medical, and defense industries. We collaborate closely with clients to develop customized solutions for prototypes or high-volume production.

3D Printing Services

Available for aerospace, automotive, medical devices, and consumer products. Material options include plastics, metals, and carbon fiber for exceptional strength and precision.

Material Options

| Material Type | Available Grades |

|---|---|

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416 |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 |

| Copper | C11000, C12000, C12000, C36000 |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 |

| Iron | A36, 45#, 1213, 12L14, 1215 |

| Plastic | ABS, PC, PE, POM, Nylon, PP, Peek |

Surface Treatment Options

| Material | Available Finishes |

|---|---|

| Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated |

| Aluminum | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing |

| Plastic | Plating gold (ABS), Painting, Brushing (Acylic), Laser engraving |

Technical Support

Our engineers are proficient in AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D software. We can develop products from drawings, samples, or conceptual ideas.

Quality Control Process

- Incoming material inspection (IQC)

- Pre-production verification

- In-process quality control (IPQC)

- Final quality inspection (FQC)

- Outgoing quality control (OQC)

Company Profile

Huizhou Yuanwenyu Precision Parts Co., Ltd. has 16 years of manufacturing experience specializing in:

- CNC machining and turning

- Sheet metal fabrication

- 3D printing services

- Custom design and manufacturing

We support customization of precision parts in various metals and plastics, with comprehensive post-processing options.

Our facility includes:

- 25 CNC machining centers

- 12 CNC turning/milling centers

- 20 CNC lathes

- 10 3D printers

- Wire cutting and grinding equipment

- Dimensional testing instruments

Why Choose Us

- Design assistance and engineering support

- OEM CNC parts specialization

- Complete production capabilities

- Advanced CAD/CAM programming

- Prototype machining

- Strict quality control standards

- Continuous equipment upgrades

- Small quantity orders accepted

Frequently Asked Questions

1. Are you a manufacturer or trading company?

We operate a 1500-square-meter factory in Huizhou, China.

2. Can I get a quote without drawings?

Yes, we can quote based on samples, pictures, or drafts with dimensions.

3. How do you protect my design confidentiality?

We strictly protect customer privacy and can sign NDAs if required.

4. Do you provide samples?

Yes, sample fees apply but may be credited against production orders.

5. What are your lead times?

Samples: 1-2 weeks; Production: 3-4 weeks.

6. How is quality controlled?

Through material inspection, production checks, sampling, and 100% pre-shipment inspection.

7. What if we receive defective parts?

We will analyze the issue and remake the parts immediately.