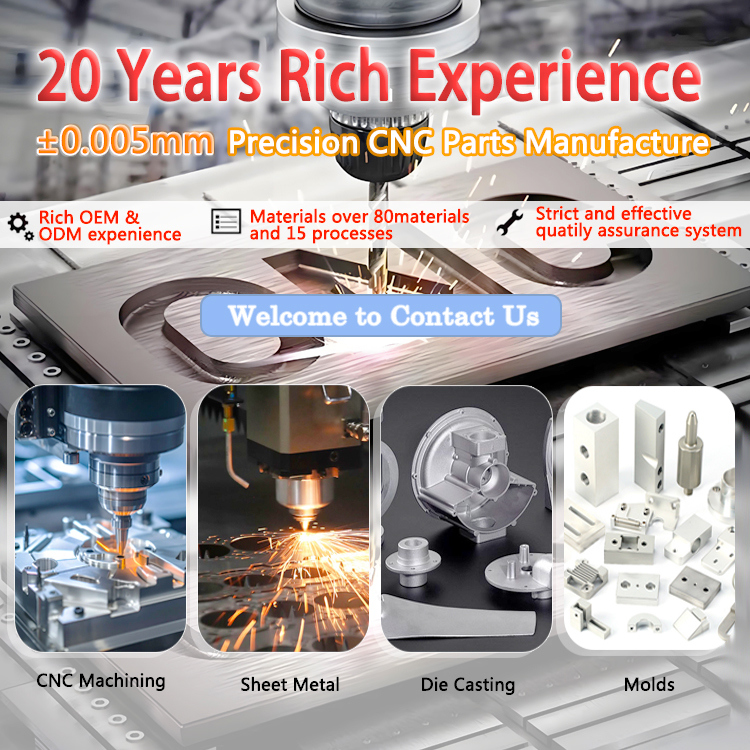

Custom Precision CNC Machined Parts with 100% Inspection and Guaranteed Quality for Brass Aluminum Steel Components

-

강조하다

Custom Precision CNC Machined Parts

,100% Inspection CNC Turning Milling Parts

,100% Guaranteed Precision Machined Components

-

용인±0.002 ~ ±0.005mm

-

표면 거칠기RA 0.1 ~ 3.2

-

재료 기능알루미늄, 황동, 청동, 구리, 경화 금속, 귀금속, 스테인리스 스틸, 강철 합금

-

표면 처리양극 산화 처리, 비드 블라스팅, 실크 스크린, PVD 도금, 아연/니켈/크롬/티타늄 도금, 브러싱, 페인팅, 분말 코팅, 부동태화, 전기 영동, 전기 연마, 널링, 레이저/에칭/

-

처리 방법CNC 전환, CNC 분쇄,, 회전하, 짓밟은 와이어 절단, 전자 방전 기기 (EDM)를 만곡시킨 레이저 커팅, 사출 성형

-

알루미늄 시리즈2000 시리즈, 6000 시리즈, 7075, 5052

-

스테인레스강 그레이드SUS303, SUS304, SS316, SS316L, 17-4PH

-

강철 등급1214L/1215/1045/4140/SCM440/40CrMo

-

황동 등급260, C360, H59, H60, H62, H63, H65, H68, H70, 청동, 구리

-

티타늄 등급F1~F5학년

-

플라스틱 유형아세탈/POM/PA/나일론/PC/PMMA/PVC/PU/아크릴/ABS/PTFE/PEEK

-

그리기 형식dxf / dwg / step / igs / pdf

-

마이크로 가공예

-

CNC 가공예

-

검사 수준임계 크기 위의 100% 검사

-

원래 장소광동, 중국

-

브랜드 이름YWY

-

모델 번호YWY021, OEM

-

문서

-

최소 주문 수량1

Custom Precision CNC Machined Parts with 100% Inspection and Guaranteed Quality for Brass Aluminum Steel Components

Custom Precision 0.01mm Tolerance Brass Aluminum Steel CNC Machined Turning Parts with Plating

Our Manufacturing Capabilities

| Processing | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

|---|---|

| Materials |

|

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Tolerance | ±0.002 ~ ±0.005mm |

| Surface Roughness | Min Ra 0.1~3.2 |

Factory Showcase

Product Gallery

Customer Projects

Frequently Asked Questions

1. Are you a manufacturer or a trading company?

We are a 1500-square-meter factory located in Huizhou, China.

2. Can I get a quote without drawings?

Yes, we can provide quotes based on your samples, pictures, or drafts with detailed dimensions.

3. Will my drawings be divulged if you benefit?

No, we strictly protect our customers' intellectual property and can sign NDAs when required.

4. Can you provide samples before mass production?

Yes, samples are available with a fee that may be refunded upon mass production order.

5. How about the lead time?

Typically 1-2 weeks for samples and 3-4 weeks for mass production.

6. How do you control the quality?

- Material inspection - Surface and dimensional checks

- Production first inspection - Critical dimension verification

- Sampling inspection - Quality control during production

- Pre-shipment inspection - 100% final inspection before delivery

7. What will you do if we receive poor quality parts?

We will immediately analyze the issue and remake the parts at no additional cost.